Manufacturing Sovereignty at the Speed of Mission

Containerized thin-film production bringing secure electronics manufacturing to forward operating bases, classified facilities, and anywhere supply chains become vulnerable.

Containerized thin-film production bringing secure electronics manufacturing to forward operating bases, classified facilities, and anywhere supply chains become vulnerable.

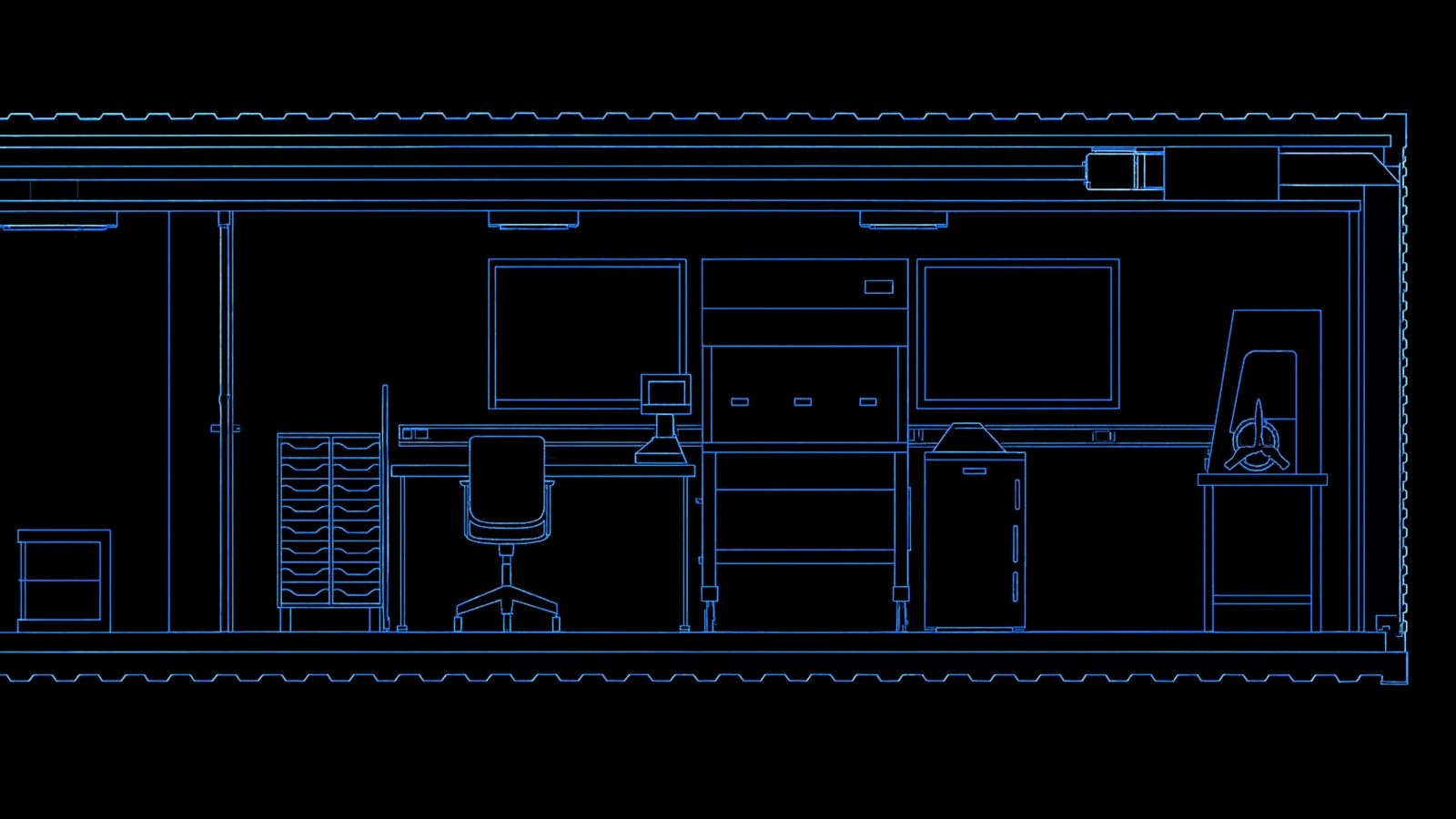

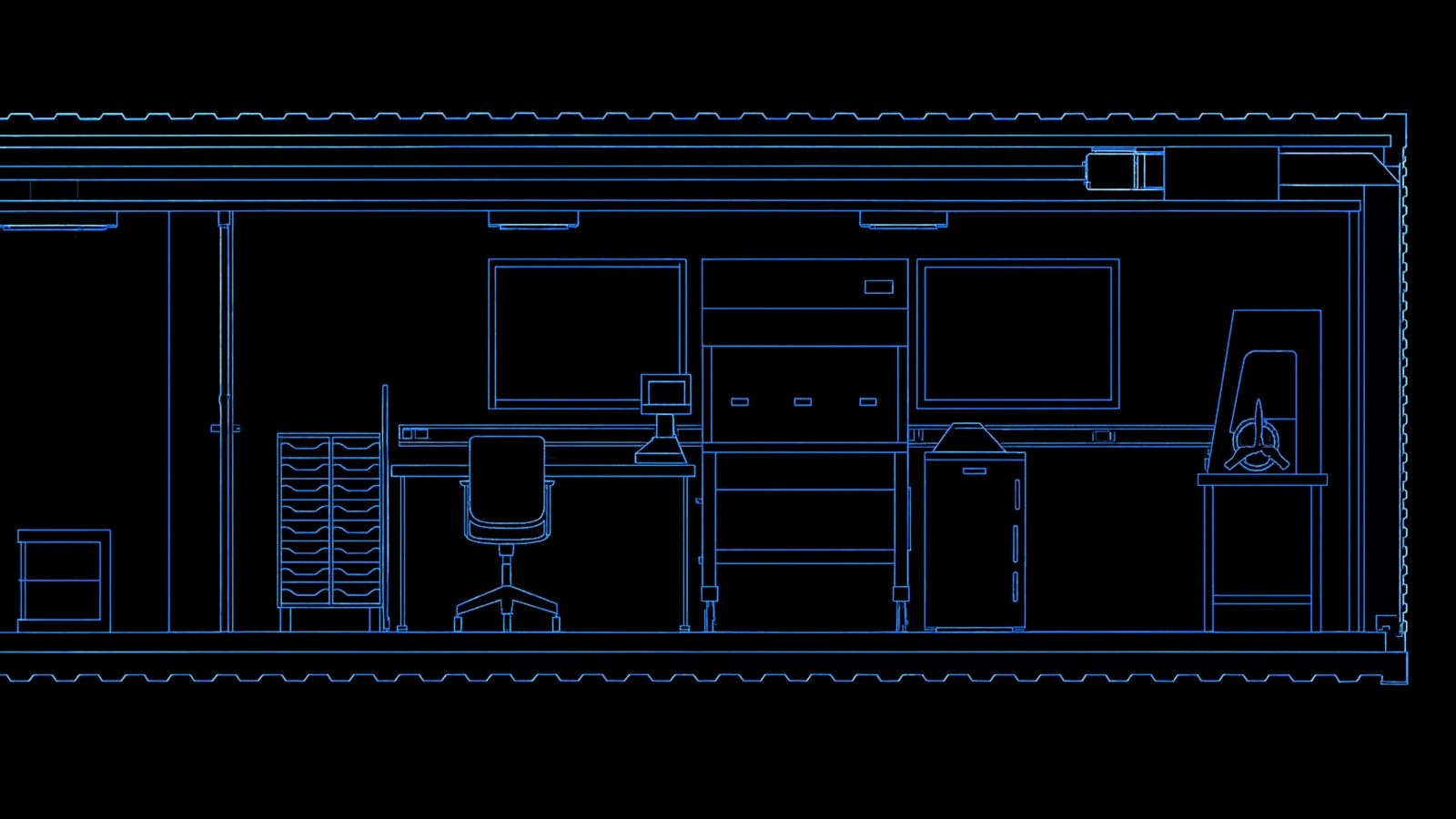

Deployable configurations ranging from Conex containers to mobile field labs on trucks and trailers. Each unit can house a complete thin-film additive manufacturing capability—printing systems, material storage, and quality control equipment. Expandable architecture allows single-unit deployment for rapid response or multi-unit configurations for higher-volume production.

Fully operational within 24 hours of arrival at location. On-grid operation using base/shore power or off-grid using generator/battery systems. Operating temperature range: -20°F to 130°F, enabling deployment in extreme environments from Arctic to desert conditions. Easily integrated into existing mobile 3d Additive Manufacturing (AM) platforms.

From raw materials to mission-ready components, R2R platforms enable secure production where sensitive IP remains within controlled facilities, no foreign manufacturing dependencies exist, components are verified at every production stage, and classification levels maintained throughout lifecycle. Reduces manufacturing costs by up to 30% while fostering a more resilient domestic industry.

Transparent conformal arrays, frequency-selective surfaces, fractal designs

Flexible hybrid electronics, printed power harnesses, data buses

Pressure, temperature, strain, environmental monitoring arrays

Printed resistive heaters, conformable thermal management films

Electromagnetic shielding, frequency denial surfaces, grounding layers

Covert taggants, authentication systems, chain-of-custody markers

Deploy manufacturing capability to contested environments where traditional supply chains cannot reach. Repair, modify, or produce electronics on-site—antennas for downed UAS, sensor replacements for ground vehicles, power harnesses for field equipment. Eliminate logistics tail and reduce dependence on vulnerable supply networks.

High-security commercial partners requiring chain-of-custody manufacturing for classified programs. Produce sensitive components on-site without exposing designs to foreign manufacturers or shared facilities. Maintain ITAR compliance throughout production lifecycle.

Sovereign manufacturing for R&D environments developing next-generation defense electronics. Rapid prototyping enables iteration cycles measured in hours, not months. Classified designs never leave controlled spaces.

Platform-agnostic systems deployable to allied forces or partner nations. Enable coalition interoperability by providing shared manufacturing capability without compromising sensitive IP. Modular units support distributed manufacturing across allied networks.

Supply Chain Warfare is Real-Waiting on foreign manufacturers isn't just slow—it's a strategic liability.

Every component sourced overseas, every design shared beyond controlled facilities, every shipment crossing contested logistics networks creates opportunities for interdiction, compromise, or IP theft. Electronics arrive obsolete, counterfeit, or don't arrive at all. And while traditional supply chains measure response time in months, adversaries evolve in days.

Every component sourced overseas, every design shared beyond controlled facilities, every shipment crossing contested logistics networks creates opportunities for interdiction, compromise, or IP theft. Electronics arrive obsolete, counterfeit, or don't arrive at all. And while traditional supply chains measure response time in months, adversaries evolve in days.

Adversaries advance electromagnetic warfare, autonomous swarms, and supply chain attacks faster than traditional procurement can respond. Mobile manufacturing enables adaptation at the speed of conflict—not the speed of contracting.

Every capability produced domestically, at the point of need, with no foreign dependencies, is a capability adversaries cannot compromise, interdict, or map. R2R manufacturing isn't just faster—it's strategically unassailable.

Contact us to explore how R2R Mobile Manufacturing can secure your operations.

Contact Us