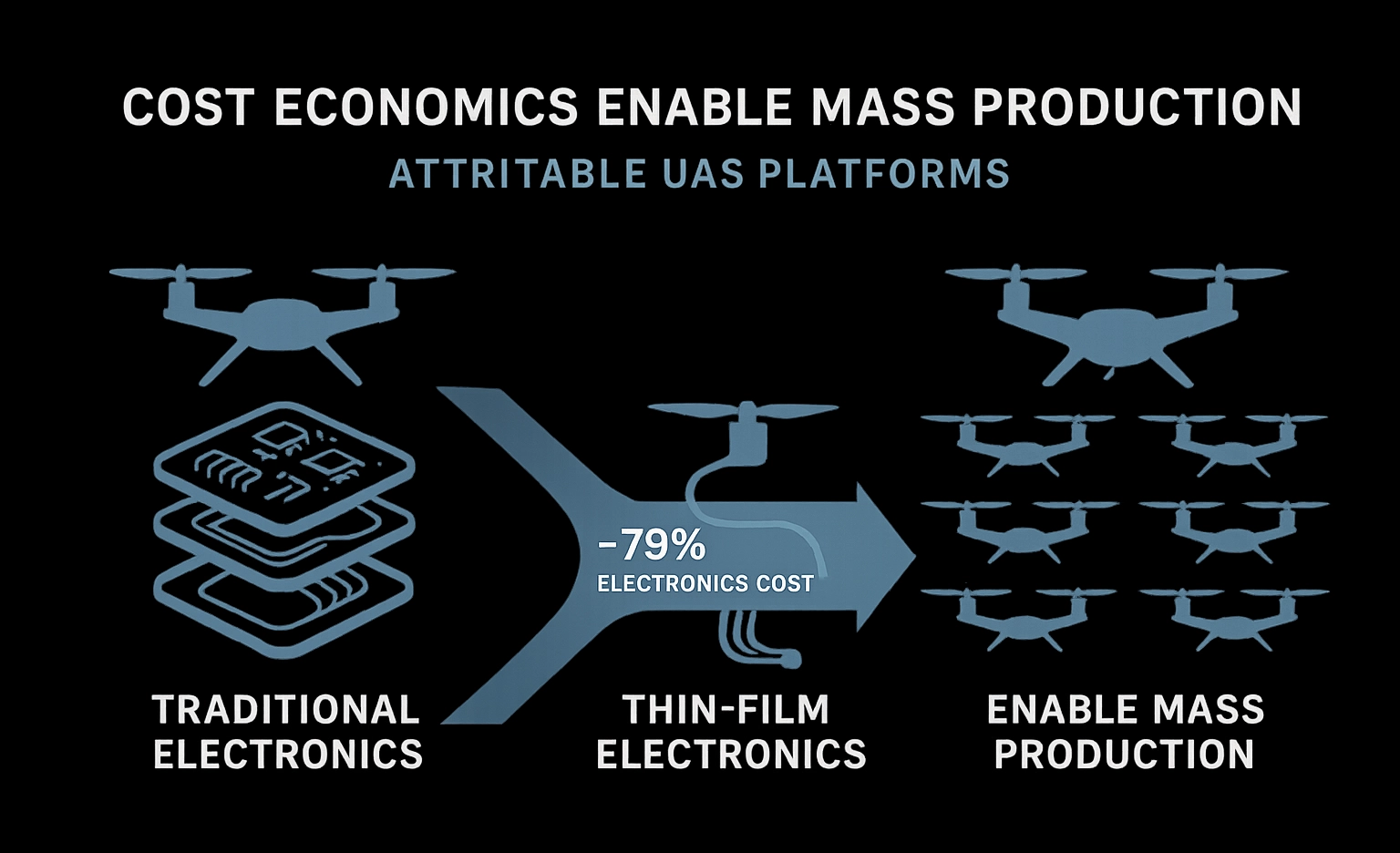

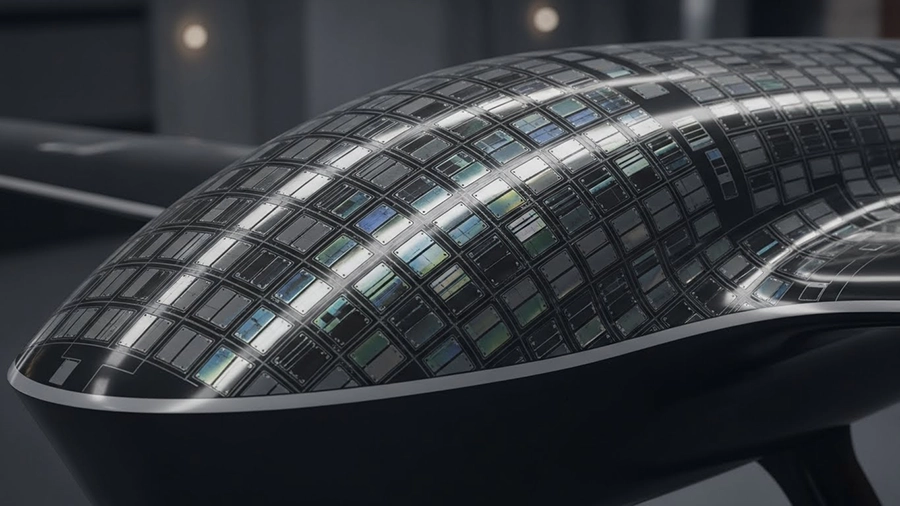

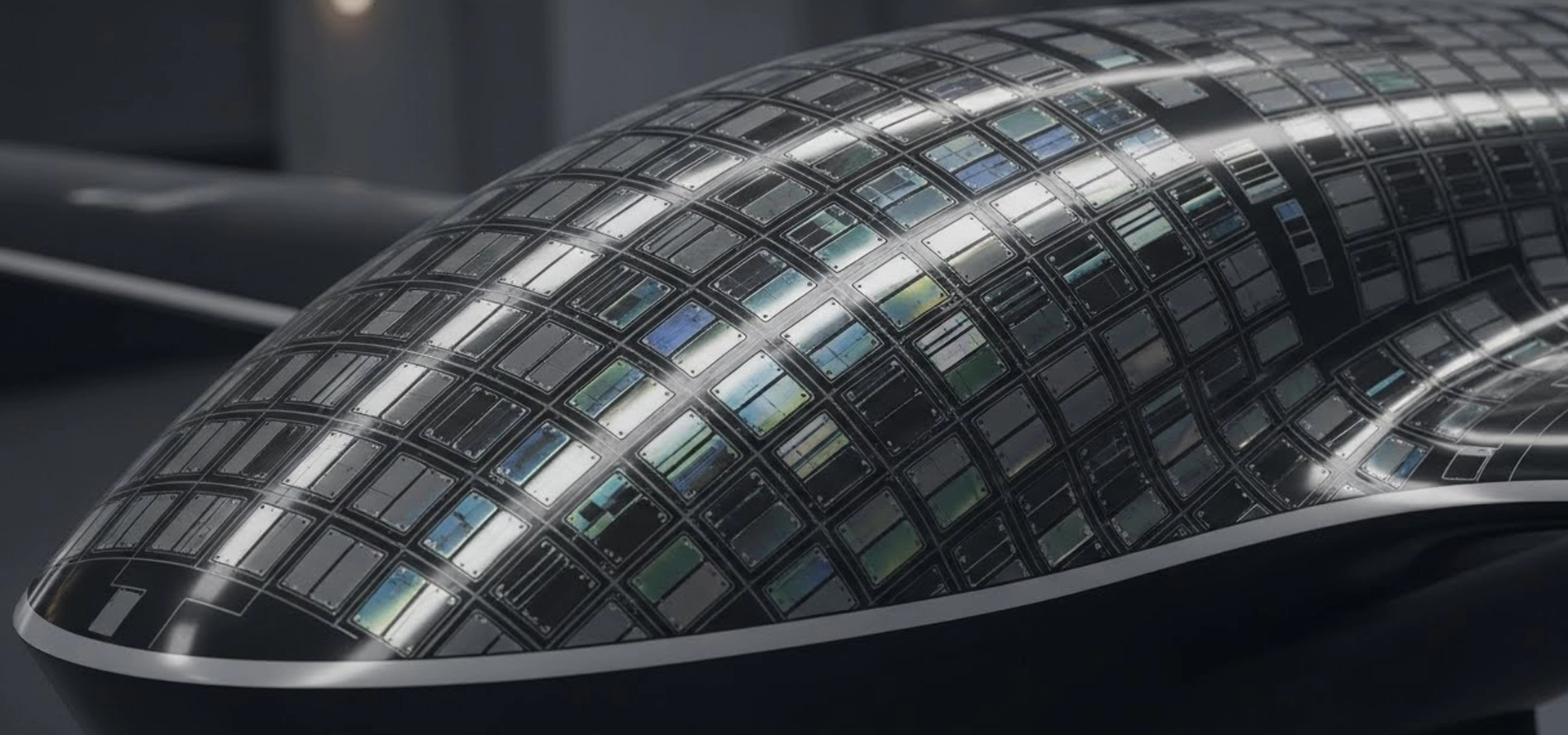

Transforming Attritable UAS: The Thin-Film Advantage

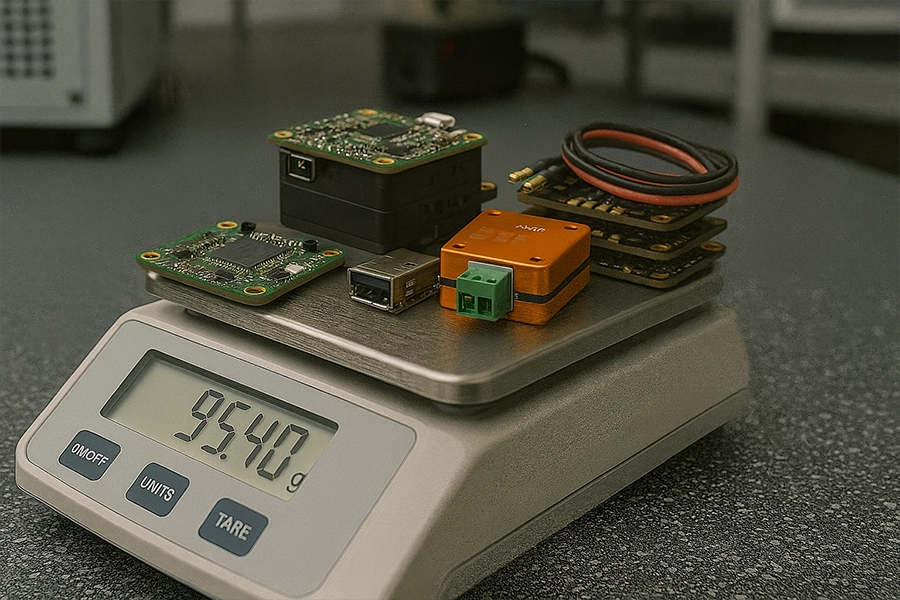

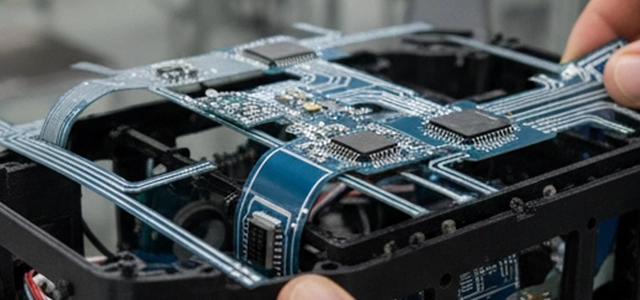

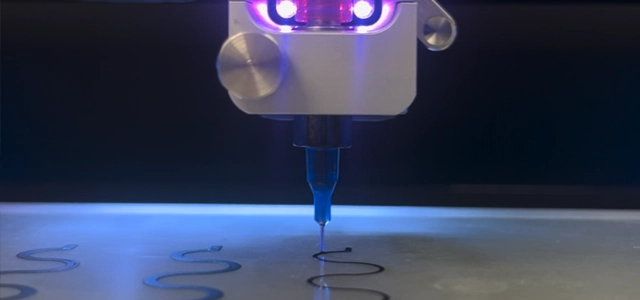

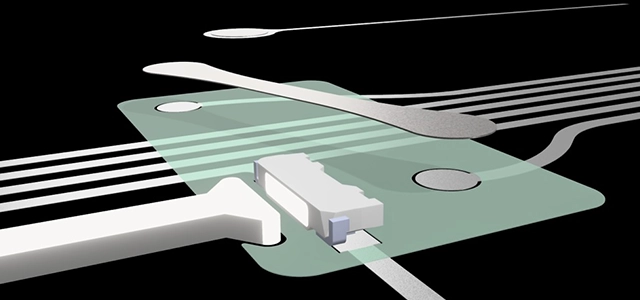

Standard Industries' thin-film technologies deliver what attritable warfare demands: radical SWAP reduction, unprecedented manufacturing speed, breakthrough cost efficiency, and forward-deployable production for groups 1-3 UAS, OWSUAS, and other attritable platforms air, land or sea.